You get what you measure, so make sure you’re tracking the right things.

I’ve seen a lot of organizations create strategies, programs, and projects focused on optimizing operations, streamlining processes, and driving innovation. Leadership teams put lots of energy coming up with the next big thing. But amazingly few teams think about how they’ll measure results. They may say they want revenue growth or cost savings, but that’s about the extent of it. Digging into the details by defining the specific metrics that will help track progress and forecast whether they’re going to achieve their goals in the future often gets neglected.

Strategy Without Successful Execution Is Just Brainstorming

Between developing strategy and executing it, there’s a step that requires creativity coupled with analytical thinking. It’s defining leading and lagging indicators. Many manufacturing companies and organizations that embrace Six Sigma know the importance of the metrics. Metrics help you quantify success, so you know when you’re achieving it and when you’re not.

Most companies focus on lagging indicators, like how much revenue they made in the last quarter, how many products they sold, or how many new customers they acquired. That’s important information, but those measures are obtained by looking in the rear-view mirror of what’s already happened. In addition to these things, you also need leading indicators to help you predict what will happen in the future. Here’s how to use both of these indicators to translate strategy into tangible implementation plans.

Leading Indicators Help You Predict the Future

Leading Indicators predict how you will perform in the future. They are more easily managed than lagging indicators but are harder to define. For example, if you’re looking to increase sales, you might measure the number of emails you send or sales calls you make. If you know that one in 10 calls results in a sale, the more contacts you make, the higher your sale forecast. Same goes for if you’re running a manufacturing organization. Leading Indicators for a manufacturing plant might include number of incidents that cause production slowdowns or the availability of specific materials in the supply chain.

Lagging Indicators Tell You How You Did

Lagging Indicators are easier to measure because they quantify what happened in the past. For example, a lagging indicator for sales would be measuring the number of products sold last month or number of new customers that signed up for a service. This information is usually easy to obtain and measure. Lagging Indicators are essential for charting progress, but are not necessarily that helpful when looking at the inputs needed for achieving your overall desired results.

Create Your Dashboard

If you want innovation, reduced costs, and greater performance, you need to figure out how to do it, and what it looks like when you get it. Creating a set of lagging indicators gives you targets to achieve. But lagging indicators without leading indicators won’t provide focus around what to do–or early warning signals that things might be off track. If you’re manufacturing products, for example, if you’re not measuring whether your suppliers are delivering your materials on time, you might get surprised one day when you realize you don’t have the raw materials you need to achieve your manufacturing targets.

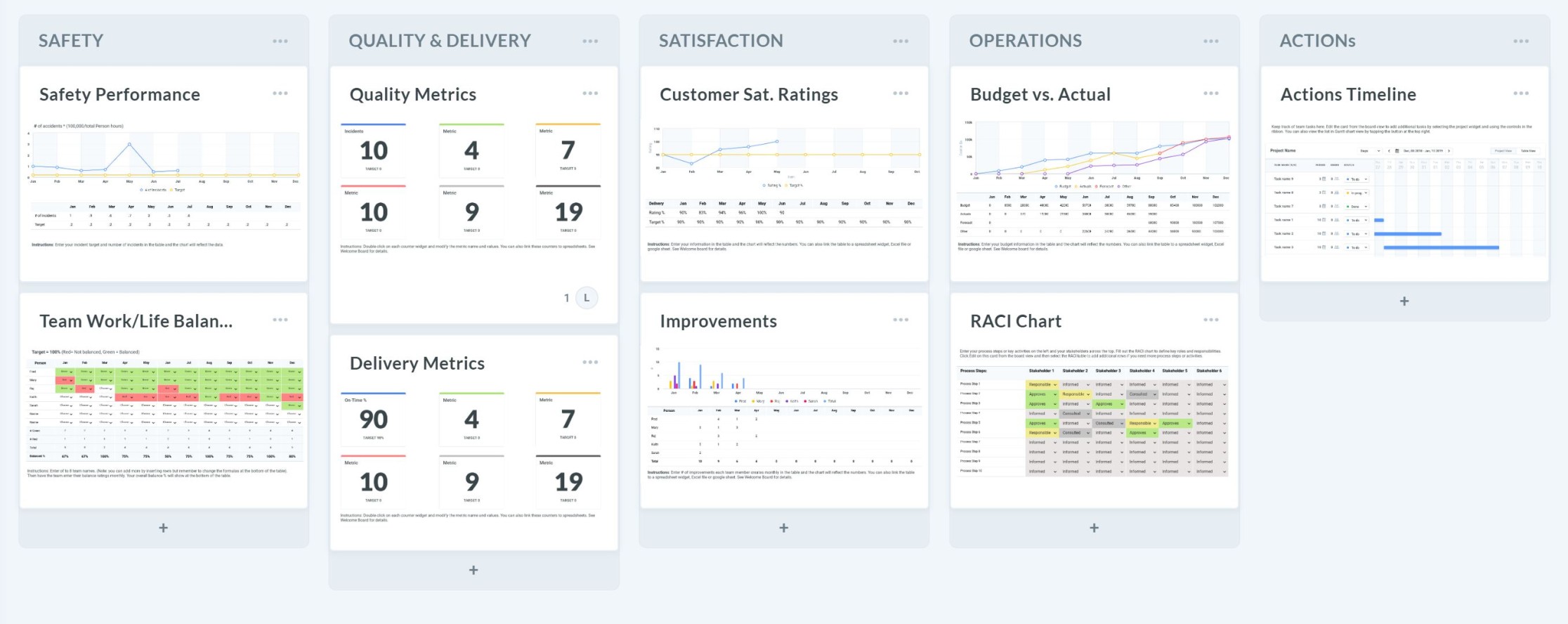

Here’s how to create a simple dashboard that contains both leading and lagging indicators:

- Convene your team and identify the specific quantifiable targets that you need to achieve (your lagging indicators). Ask: What does success look like and how do we measure it?

- Once you have your lagging indicators, define the inputs needed to achieve them. Ask: What specific things need to happen for us to achieve these targets and how do we measure those things? (your leading indicators)

- With your lagging and leading indicators defined, use specific tools to gather and report on your data, whether a spreadsheet or online dashboard.

Management guru Peter Drucker once said, “What’s measured, improves.” If you want to improve your processes and business, figure out what you’re measuring. If you measure only the outputs (lagging indicators), your success will be far less predictable than if you’re also measuring the things that will get you where you want to go.

Soren Kaplan is the best-selling and award-winning author of Leapfrogging and The Invisible Advantage, an affiliate at USC’s Center for Effective Organizations, a columnist for Inc. Magazine, a leading keynote speaker and the founder of Praxie.com. Business Insider and the Thinkers50 have named him one of the world’s top management experts and consultants.